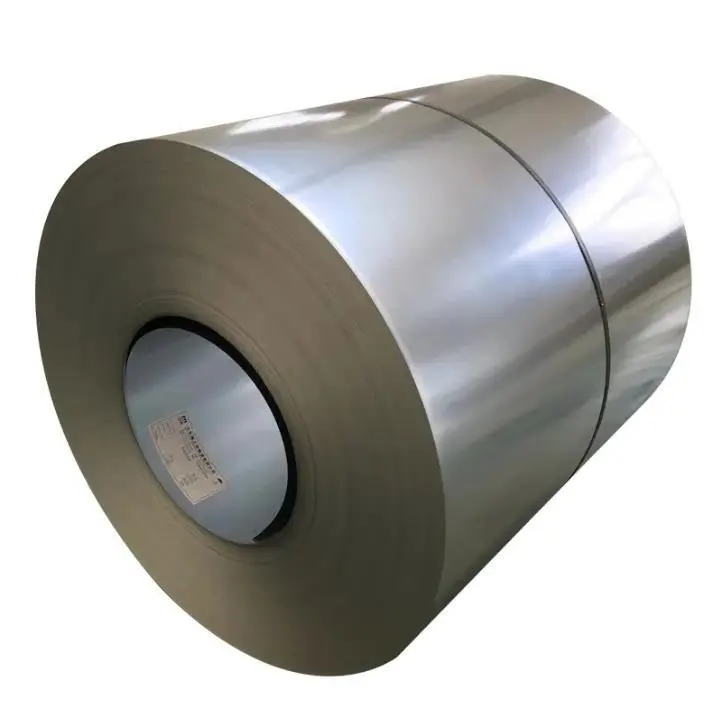

Galvalume Steel Coil sheet Supplier

Galvalume coil introduction

Galvalume coil is also known as aluminized zinc coil

Aluminized zinc coil refers to the color steel plate made by cold rolling or hot rolling on the zinc surface with zinc as the substrate and aluminum as the surface coating. Aluminum-plated zinc coil has been widely used in the construction industry because of its excellent appearance, high corrosion resistance, easy processing and installation. First of all, the aluminized zinc coil has a high-quality appearance.

Usually, the zinc surface has to be measured and sandblasted, and the surface finish and coating effect are high, which makes the aluminized zinc coil have stronger corrosion resistance and anti-aging properties. Secondly, aluminized zinc coil has high corrosion resistance, and its surface has good corrosion, which can effectively resist acid rain and other damage under various climatic conditions.

In addition, aluminized zinc coil is easy to process and can be processed by various processing methods such as hot dip galvanizing equipment, cold rolling equipment and rolling equipment to meet the requirements of different occasions. Finally, its installation is simple and convenient, and it can be easily and quickly installed on the surface of the building by drilling, pasting and other installation methods. In short, the high-quality appearance and high corrosion resistance of aluminum-plated zinc coil make it widely used in the construction industry.

In addition, aluminized zinc coil also has the characteristics of easy processing and easy installation, making it more practical. Therefore, more and more customers begin to choose to use aluminized zinc coil. Aluminized zinc coil as a new type of building materials, through the continuous improvement of research and development technology, strive to achieve its delivery of high quality performance to meet customer requirements.

With the development of technology, the application prospect of aluminum-plated zinc coil in the construction industry will be more and more broad, and it will also provide more possibilities for the construction industry.

Material analysis of aluminized zinc coil

First, the basic properties and characteristics of aluminum-plated zinc coil

Aluminized zinc coil is a material made of zinc aluminum alloy coated on the surface of steel plate after a series of process treatment. It has the following characteristics:

1. Strong corrosion resistance: the surface of aluminized zinc coil has zinc and aluminum elements, which can effectively resist the erosion of atmospheric, water, acid, alkali and other chemical substances, and increase the service life of the steel plate.

2. Good high temperature resistance: the surface coating of aluminized zinc coil uses high temperature baking paint, which can maintain the color and luster of the surface at high temperature, and will not fade.

3. Good processing performance: aluminum plated zinc coil has excellent processing performance, can be shear, stamping, bending and other processing, made into different shapes of components and parts.

Second, the material composition of aluminum plated zinc coil

The base material of the aluminized zinc coil is steel plate, the surface is coated with zinc aluminum alloy layer after treatment, and then subjected to high temperature baking paint treatment. Among them, zinc-aluminum alloy is composed of aluminum, zinc, silicon and other metal elements. The main production process of aluminized zinc coil includes coil, cleaning, zinc and aluminum alloy melting coating, drying, high temperature painting and other processes.

Third, the application range and advantages of aluminum-plated zinc coil

Aluminum-plated zinc coil is mainly used in construction, home appliances, transportation and other fields. In the field of construction, aluminum-plated zinc coil is widely used in steel structure houses, building exterior walls, roofs, chimney ventilation pipes and other parts, because of its bright appearance and bright color, it has become a new type of building decoration material. In the field of home appliances, the electrical surface made of aluminized zinc coil after processing has a beautiful appearance and is widely used in the field of home appliance manufacturing. In the field of transportation, aluminum plated zinc coil is widely used in body, cargo box, wheel hub and other parts, its high strength, corrosion resistance characteristics, can effectively protect the service life of auto parts.

Our product features

The difference between aluminized zinc coil and galvanized coil

First, the material is different

Galvanized coil is made of low carbon steel coil as the base material, after pickling, washing, drying and a series of processes, and then hot dip galvanized. On the basis of galvanized coil, aluminum, zinc and other metal elements form a composite coating with the substrate through electrolytic deposition technology. Therefore, there is a clear difference between the two materials.

Second, the process is different

The process of manufacturing galvanized coil is relatively simple, and its main process is pickling, washing, drying, hot dip galvanizing and cold rolling. The process of aluminum-zinc plating coil is more complex, its main process includes pickling, washing, drying, hot dip galvanizing, electrolytic deposition layer, drying, cold rolling and other links.

Three, different characteristics

Galvanized coil has the characteristics of anti-corrosion, anti-rust, beautiful and so on, but after a period of use, the surface is easy to produce rust spots, rust spots and other corrosion phenomena. Aluminized zinc coil is a new type of metal material, and its coating contains aluminum, zinc and other metal elements, which can effectively improve the corrosion resistance and weather resistance of the material, and has excellent weather resistance, corrosion resistance and decorative.

Four, Different applications

Due to the difference in characteristics, the two are also different in application. Galvanized coil is widely used in construction, automobile, electrical, furniture and other fields; In addition to the use of galvanized coil, aluminum coated zinc coil is also widely used in Marine, chemical, power station, climate and other more demanding working environment.

Aluminum in liquid zinc

It is added as a beneficial element, for general galvanized products and iron-zinc alloy products, aluminum is added as an alloy element to improve performance, and for aluminum zinc and galvanized aluminum products, aluminum becomes an important part of the coating, so the role of aluminum is greater. The following only describes the effect of aluminum in galvanizing and iron-zinc alloy products.

(1) The role of aluminum on the galvanizing process has two aspects: first, aluminum inhibits the reaction of iron and zinc, and after the steel strip enters the zinc liquid, aluminum first reacts with iron to form a dense film of iron and aluminum compounds, which inhibits the diffusion of iron, so that the formation and thickening of the iron-zinc compound layer is hindered. Second, aluminum is conducive to the floating removal of zinc slag, which is also because aluminum is more active than iron, aluminum can replace the iron in the zinc slag, forming aluminum zinc compounds, so as to float away.

The effect of aluminum on galvanized products also has two aspects:

First, aluminum improves the adhesion of the coating, and the iron-aluminum compound layer can play the role of the medium, so that the steel base and the coating are closely combined together, which can improve the stamping and forming performance of the galvanized sheet, and will not cause the coating to fall off during deformation.

Second, aluminum can improve the uniformity of galvanized sheet, aluminum makes the coating less affected by the iron-zinc reaction, the thickness of the coating is uniform, and at the same time improve the appearance of galvanized products.

How to choose the right galvalume coil

First, understand the basic properties of aluminum-plated zinc plate.

Before purchasing aluminized zinc plate, we first need to understand its basic performance. Aluminized zinc plate is an alloy coated steel plate composed of aluminum, zinc and a small amount of other metal elements. This coating has good corrosion resistance, especially in high temperature, humidity and other harsh environment performance is more prominent. In addition, aluminized zinc plate also has good heat resistance, processability and weldability, and is widely used in construction, home appliances, automobiles and other fields.

Second, pay attention to product specifications and parameters.

Different application scenarios have different requirements on the specifications and parameters of aluminum-plated zinc plates. When purchasing, it is necessary to pay attention to the key parameters such as the thickness, width, length and galvanized amount of the product according to the actual needs. For example, the construction field usually needs to use thicker aluminum-plated zinc plates to ensure load-bearing capacity and stability, while the home appliance field does not have high requirements for the thickness of the plates. Therefore, when selecting aluminized zinc plate, it is necessary to select the appropriate product specifications and parameters according to the actual needs.

Third, consider the price and cost performance.

In the purchase of aluminum plated zinc plate, price is also a factor that cannot be ignored. Different brands, specifications and parameters of aluminized zinc plate prices may be greatly different. In the pursuit of good products at the same time, also need to pay attention to its cost performance. It is suggested that in the selection, a number of manufacturers for price comparison, combined with product performance, after-sales service and other aspects of comprehensive evaluation, choose cost-effective products.

FAQ

Leave A Message

get in touch with us

Contact Us

Contact Person: Toby

Phone: 0086 187 2258 3666

E-mail: toby@henghuisteel.com

WhatsApp: 0086 185 2672 0784

Add: Daqiuzhuang Industrial Park, Jinghai District, Tianjin