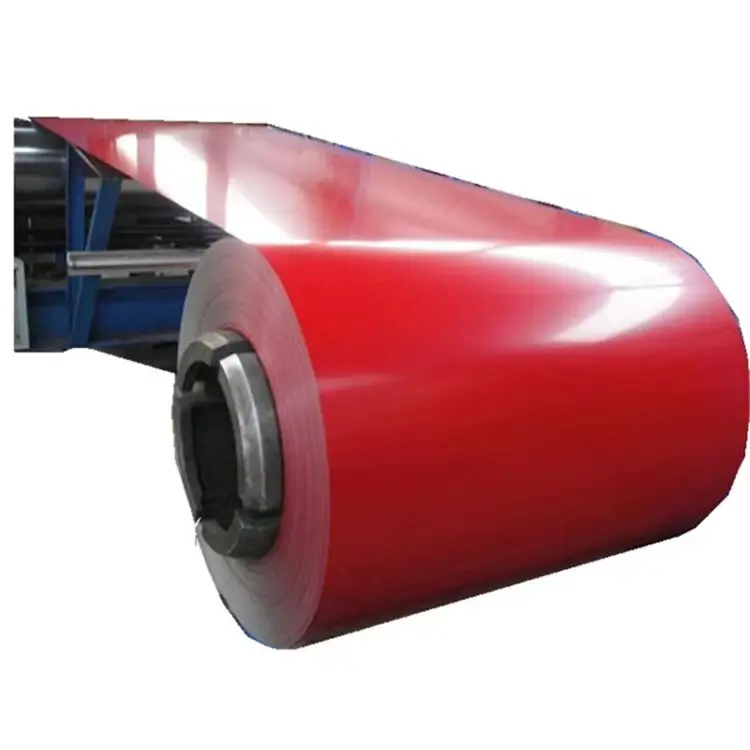

Ppgi Steel Sheet 0.15-2mm,600-1800mm by HengHui Steel

Product details of the ppgi steel sheet

Product Description

HengHui Steel ppgi steel sheet is designed and manufactured under the supervision of experts by employing the latest technology following industry standards. Through the careful inspection of the professional QC team, HengHui Steel product is 100% qualified. The excellent quality control throughout all stages of ppgi steel sheet production ensures top quality.

Hot-dip galvanized substrate

The product obtained by coating the organic coating on the hot-dip galvanized steel plate is the hot-dip galvanized color coated plate. In addition to the protective effect of zinc, the organic coating on the surface also plays a role in isolating protection and preventing rust, and the service life is longer than that of the hot galvanized sheet. The zinc content of hot-dip galvanized substrate is generally 180g/m2 (double-sided), and the maximum galvanizing amount of hot-dip galvanized substrate for external construction is 275g/m2.

Zinc plating substrate

Electrogalvanized plate as the substrate, coated with organic coating baking products for electrogalvanized color coated plate, because the zinc layer of electrogalvanized plate is thin, usually contains zinc content of 20/20g/m2, so the product is not suitable for use in outdoor production of walls, roofs, etc. However, because of its beautiful appearance and excellent processing properties, it can be mainly used for household appliances, audio, steel furniture, interior decoration and so on.

Hot aluminized zinc substrate

The hot-plated aluminum zinc steel plate (55%Al-Zn) is used as the new coating substrate, usually containing 150g/㎡ of aluminum zinc (double-sided). The corrosion resistance of hot plated aluminum zinc plate is 2-5 times that of hot galvanized plate. Continuous or intermittent use at temperatures up to 490 ° C will not result in severe oxidation or oxide skin. The ability to reflect heat and light is 2 times that of hot galvanized steel, and the reflectivity is greater than 0.75, which is an ideal building material to save energy.

Our inventory specifications

Galvanized steel plate :

Size: length,1500-2500,width,600-1500,thickness,0.3-2mm

Product delivery time

As for the delivery time, it can be controlled by the customer. Because we are a physical factory and cooperate with many large steel mills in China, the time error can be controlled within about 3 days, and we provide free warehousing service

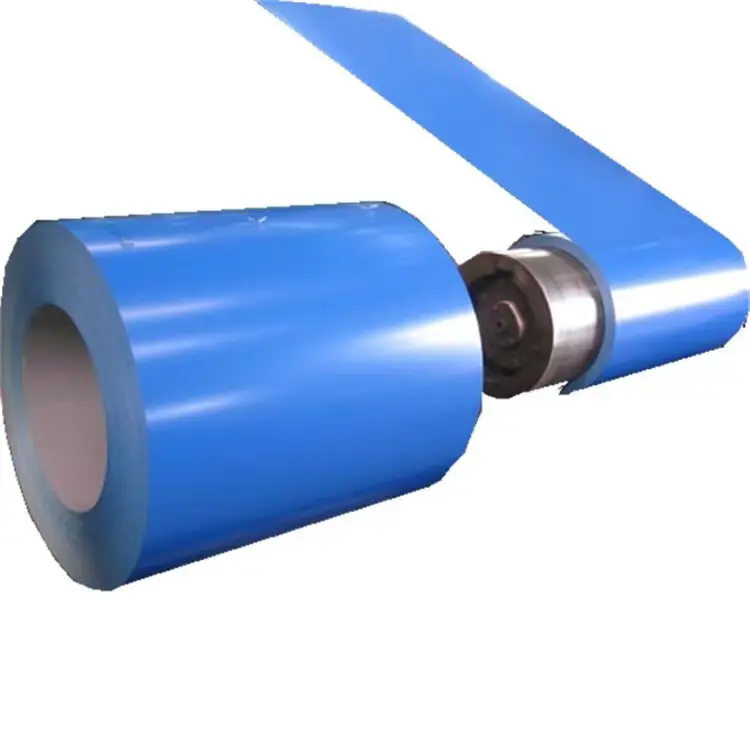

Color coated roll use

Color coated roll has light weight, beautiful appearance and good corrosion resistance, but also can be directly processed, the color is generally divided into gray, blue, brick red, mainly used in advertising, construction, home appliance industry, electrical appliance industry, furniture industry and transportation industry.

The paint used in the color coating volume is selected according to the different use environment, such as polyester silicon modified polyester, polyvinyl chloride plastisol, polyvinylidene chloride and so on. Users can choose according to the use.

Our product features

Substrate selection The base material of color coated steel coil mainly includes cold rolled steel plate and galvanized plate. When selecting the substrate, it is necessary to consider its performance characteristics, thickness, flatness and other factors to ensure the quality and use effect of the color coated steel coil.

Surface treatment The substrate is first surface treated to prepare it for the next step of coating. The surface treatment process includes oil removal, pickling, alkali washing, phosphoric acid treatment and other processes. These processes can effectively remove impurities such as dirt and oxide sheet from the surface of the substrate, while improving the adhesion and corrosion resistance of the substrate surface.

Coating production After the surface treatment, the substrate is sent to the coating line for coating. The production process of the coating includes three steps: base coating, top coating and varnish. In the bottom coating process, epoxy, polyester and other primers are generally selected for coating.

In the top coating link, it is mainly the choice of color and the treatment of the appearance effect, using PVDF, PE, HDP and other resins as coating materials, so that the color coated steel coil has different colors and glossness on the surface. The main part of the varnish is to increase the gloss of the coating and improve the anti-fouling performance.

Solidify After finishing the coating, the color-coated steel coil needs to be cured by baking. During the baking and curing process, the color coated steel coil is sent into a high temperature oven, and different temperatures and times are set according to the different materials selected. Through curing, the coating material can be fully reacted and cross-linked, thereby improving the performance indicators such as weather resistance, hardness and adhesion of the color coated steel coil.

Cutting and packing After the above process, the color-coated steel coil needs to be cut and packaged after it is made. Cutting is mainly to cut the color coated steel coil into the required size according to customer needs and product specifications. Packaging is to cut the color coated steel coil for packaging, so as to avoid external pollution and damage.

Our inventory specifications

PPGI COIL:0.15-2mm,600-1800mm

Place of Origin:TianJin,China

Product delivery time

As for the delivery time, it can be controlled by the customer. Because we are a physical factory and cooperate with many large steel mills in China, the time error can be controlled within about 3 days, and we provide free warehousing service

FAQ

Company Feature

• Since it was established in our company has been focusing on the research and development and production of main products for years. So far, we have accumulated a large amount of professional knowledge and rich production experience.

• With high-quality technology research team and production team, independently develops and research the products by using advanced technology and methods.

• HengHui Steel's Welded pipe,galvanized steel pipe,galvanized coil,color coated coil,scaffold product,black annealed steel pipe,hot dipped galvanized steel pipe are of good quality and competitive price. And the sales network covers from provinces, municipalities and autonomous regions to many developed countries and regions.

• Our company has always adhered to the service concept of 'based on integrity and treat people sincerely', and we provide considerate one-stop service for consumers to solve problems promptly.

HengHui Steel is willing to serve our customers with perfect quality, reasonable price and excellent service. Welcome to cooperate with us and work together to create brilliance.

Leave A Message

get in touch with us

Contact Us

Contact Person: Toby

Phone: 0086 187 2258 3666

E-mail: toby@henghuisteel.com

WhatsApp: 0086 185 2672 0784

Add: Daqiuzhuang Industrial Park, Jinghai District, Tianjin